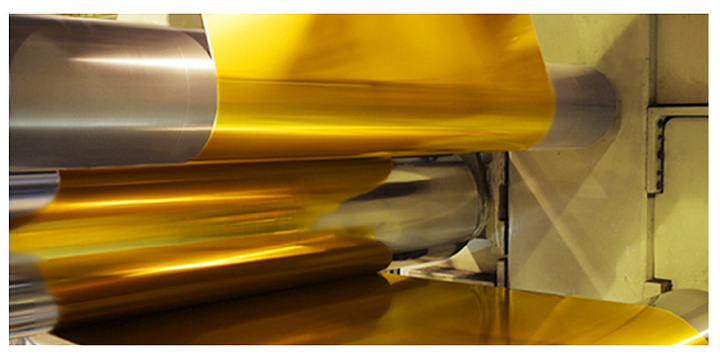

Coated Aluminium foil for Container and its lid

Signi Coat’s aluminium coated foil could be used for production of semi-rigid containers and its lids for food packaging. Due to its unique properties, Signi Coat’s aluminium coated foil is ideal for the reduction of cooking time, cooling and heating, thanks to an excellent thermal conductivity. Besides it provides a high barrier protection for light, gas and contamination, that improves the food conservation. With the aluminium lid, the food could be heated in air furnaces and ensure the preservation of an optimum temperature and a good state of food longer, being light weight and resistant to external agents at the same time.

Features:

1.Very good heat conductivity, that makes it suitable for freezing and re-heating.

2.Light weight that allows economizing on shortage and transport space.

3.Food can be heate by convection, fan or microwave oven.

4.Extraordinary properties for inlaying, with lacquers especially developed by our technical department for single inlay process as well as double inlay.

With above good features, our foils could be made:

Container for heat processed dairy desserts.;

Container for prepared and oven ready meal.

Container for ready to cook-frozen deserts.

Airline catering printing lids.

High-speed train catering printing lids.

Specification:

Alloy: 8011, 8006, 3003 and 3105

Temper: H14

Thickness: 0.04mm up to 0.1mm.

Coating lacquer: Colorless or white lacquer on one side, and plain, colorless, white, coloured lacquered or printing on the other side, lubrication is optional.

Coating properties:

Epoxy based lacquers with excellent adhesion to aluminium foil(resistant to adhesive tape test), good solvent resistance, good friction resistance and good resistance to dry heating(2 min./240℃). Different colours vailable on customer request. Thickness of coating depends on colour.

White lacquer:

Polymerization > 50 double rubs/MECK.

Coloured lacquer:

Polymerization > 50 double rubs/MEK.

Colourless lacquer:

Polymerization> 35 double rubs/MEK.

Printing inks:

Special inks developed for this application, resistant to heating and freezing.

Lubricant:

Lubrication is optional. Quantity can be specified by the customer.

Contact Form