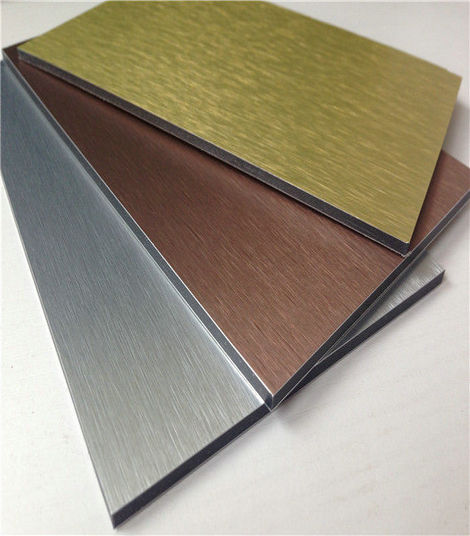

Heat transfer print aluminum board is a new technology that prints pattern on heat-resistant offset paper, and then uses the principle of thermal sublimation, through pressure, heating and other technical measures, the pattern of oil film is printed on specially treated medium. Through innovative technology, the company applies this technology to aluminium veneer, thermal transfer printing. Aluminum veneer with its lifelike and lasting pattern performance, brings broad market prospects.

Specifications and sizes of heat transfer textured aluminium board:

Heat transfer print aluminum board substrate dimensions: thickness 2.0 mm, 2.5 mm, 3.0 mm, 4.0 mm, 5.0 mm, 6.0 mm

Width 1000mm-1900mm and length less than 6000mm

Heat transfer print aluminum board routine dimensions of finished products: Machinable forming length less than 6000 mm, width less than 1500 mm, height less than 1.9 mm.

Special plate size: conventional arc plate forming radius (> 150mm) special open die

Punch hole diameter < 80mm hole shape, size and spacing can be customized according to customer requirements.

Advantages of Heat Transfer Textured Aluminum Veneer Products

01 Substrate adopts corrosion resistant and high strength alloy aluminium sheet or galvanized steel sheet.

02 coating has excellent chemical activity and physical properties to match the printing effect of ink.

03 coating has excellent deep processing performance, which meets the deep drawing requirements of shel