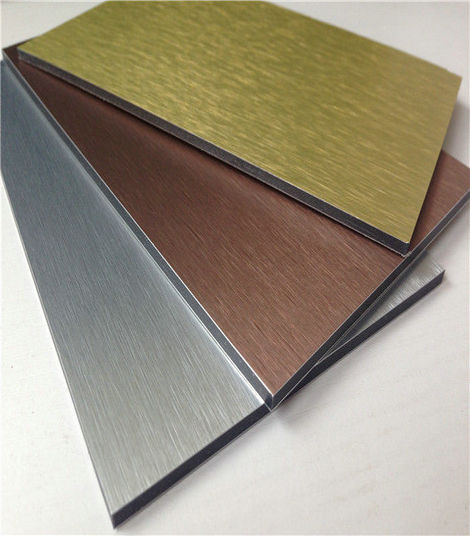

Brushed color coated aluminum sheet is the process of repeatedly scraping the aluminum plate with sandpaper. The main process is divided into 3 parts: deesterification,sand mill and water washing. In the drawing process of aluminum sheet, the special coating technology after the anode treatment can make the surface of the aluminum sheet produce a kind of coating layer containing the metal composition, clearly showing each fine microfilament mark, thus making the metallic Matt light shiny. In recent years, more and more aluminum products have been made of metal brushed color coated aluminium sheet technology to make them beautiful and corrosion resistant. Make the product both the elements of fashion and technology. This is also one of the reasons that the process is popular.

Henan signi aluminium can do color coated brushed aluminum sheet as follow

Alloy:1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc.

Thickness :0.2~0.8mm

Width:<1600mm

Color:As to code RAL

Gloss:10-90%(EN ISO-2813:1994)

Total coating thick:PVDF27 ~35micron,Polyester18~27micron(EN ISO-2360:1995)

Coating hardness: 2H

Adhesion:5B (EN ISO-2409:1994)

Impact resistance: No cracking and peeling (A.S.T.M D2794-1993)

Color coated aluminum brushed sheet applications

Exterior applications: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

Interior applications: wall cladding, ceilings, bathrooms, kitchens and balconies

Advertisement and market applications: display platforms, signboards, fascia and shop fronts